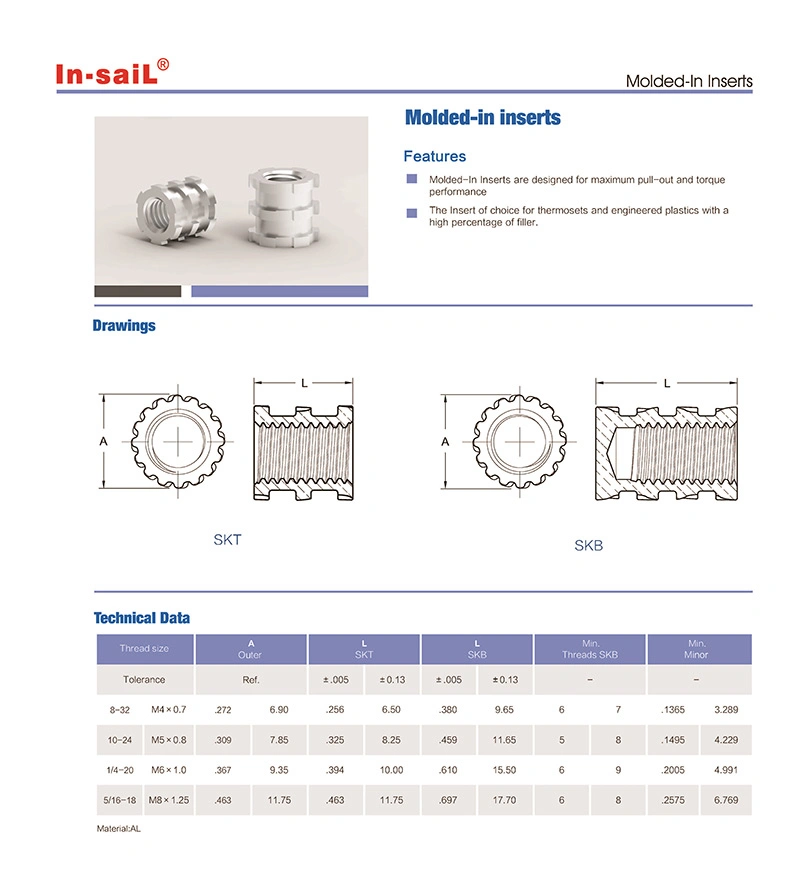

Series 63 and Series 65 Threaded Aluminum Inserts for Automotive Industry

Aluminum insert for audio speakers on truck In-saiL is pleased to introduce a high-performance line of Molded-in Inserts

Description

Basic Info.

| Model NO. | Spirol Series 63 65 |

| Management System | ISO9001:2008 |

| Finish | Zn/Ni/Tin Plating,Electroplating, Anodizing etc. |

| Lead Time | 5-10 Working Days |

| Certification | SGS,RoHS,Material Certication,Ppap |

| Item Name | Brass Fasteners |

| Transport Package | PE Bag + Cartons |

| Specification | SGS |

| Trademark | In-saiL |

| Origin | Shenzhen, China |

| HS Code | 7616100000 |

| Production Capacity | 100K PCS/Week |

Product Description

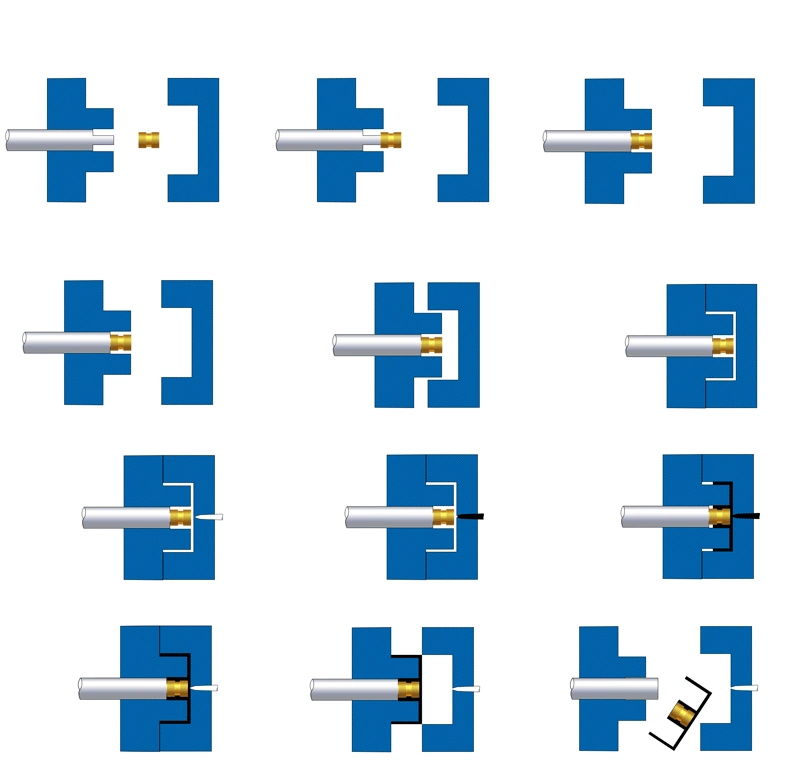

Aluminum insert for audio speakers on truckIn-saiL is pleased to introduce a high-performance line of Molded-in Inserts for Plastics manufactured from aluminum. The robust design of the Series SKB Blind-End and Series SKT Through-Hole Inserts consists of axial grooves to maximize torque resistance, balanced with radial undercuts to achieve high-pull out force. These Molded-in Inserts are designed to be placed in the mold cavity prior to plastic injection and offer exceptional performance due to unrestricted plastic flow into the retention features on the outside diameter of the Inserts.

These lightweight Threaded Inserts for Plastics are manufactured from 2024 grade aluminum which provides the best combination of strength, corrosion resistance, machinability, and cost. The Series 60 and Series 61 Molded-In Inserts are lead-free, 40% stronger than brass, and 1/3 the weight of the same Insert manufactured from brass. Standard inch thread sizes include 8-32, 10-24, 1/4-20, and 5/16-18, and M4, M5, M6, and M8 for metric thread sizes.

In-saiL offers a comprehensive line of Inserts for Plastics including Press-In, Expansion, Self-Tapping, Heat/Ultrasonic, and Molded-In styles to accommodate specific performance and installation requirements!

| Material | Brass,Stainless Steel,Carbon steel,Aluminum alloy,according to customer's requirement |

| Finish | Zn/Ni/Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting, powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Insert Methods | By Ultrasonic,Heat staking,Insert Molding,Cold press-in Methods |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max | |

| Lead Time | 5-10 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Our Contact

Send now